What is Tungsten Carbide Powder?

Tungsten carbide powder is a high-performance material known for its exceptional hardness and resistance to wear. Learn more about its uses and properties in high-temperature applications.

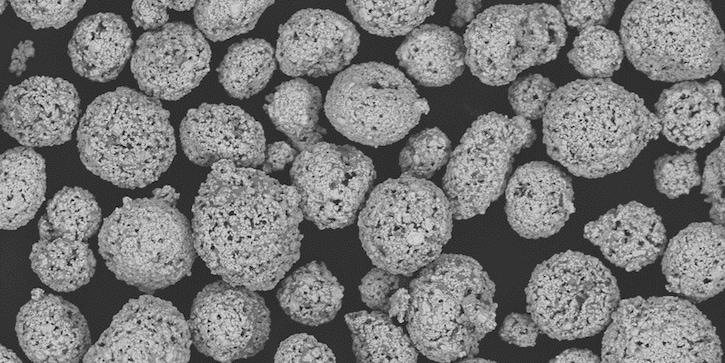

SEM micrograph of a standard WC/Co Cermet powder produced by Linde Advanced Material Technologies for thermal spray coatings.

Tungsten carbide powder provides exceptional hardness and when mixed with a binder to form a cermet or cemented carbide, gives remarkable wear resistance. This engineered material, composed of tungsten and carbon atoms in a precise crystalline structure, has revolutionized manufacturing processes across multiple industries. As global demands for high-performance materials grow, industrial professionals and engineers seeking optimal material solutions should understand tungsten carbide powder's characteristics, applications, and benefits.

Related: What are metal powders?

An Introduction to Tungsten Carbide Powder

Characteristics

Tungsten carbide powder consists of uniformly sized particles, typically ranging from submicron to several microns in diameter, with a dark gray appearance characteristic of its composition. Its grain structure can be precisely controlled during manufacturing, allowing for optimization based on specific application requirements. When combined with a binder such as nickel or cobalt to form a c ermet powder, the powder's morphology plays a critical role in its performance, with modern processing techniques producing highly spherical particles that enhance flowability and packing density.

Properties

Tungsten carbide powder's properties make it invaluable for industrial applications. Its hardness is second only to diamond among industrial materials, and it resists wear and maintains its properties at high temperatures. The material's high elastic modulus contributes to its outstanding rigidity, while its thermal conductivity exceeds that of many comparable materials. These properties remain stable across a wide temperature range, making tungsten carbide powder suitable for demanding industrial environments. The powder's compressive strength significantly surpasses most engineering materials, contributing to its durability in high-stress applications.

Composition

Tungsten carbide powder consists of tungsten and carbon atoms bonded in crystalline structures. The stoichiometric ratio typically follows the chemical formula WC, though variations exist depending on specific application requirements. The powder's composition can be modified by adding binding materials or other carbides to enhance particular properties. Manufacturing processes carefully control carbon content and impurity levels to ensure optimal performance characteristics, with modern production methods achieving exceptionally high purity levels exceeding 99.9%.

Related: What is tungsten carbide?

The Uses and Applications of Tungsten Carbide Powder

Industrial and Manufacturing Sector

Tungsten carbide powder is used in manufacturing cutting tools, wear-resistant components, and high-performance coatings. The material's hardness makes it ideal for creating cutting inserts used in metalworking, mining equipment, and oil drilling tools. The powder can be applied through thermal spray as protective coatings on components subject to severe wear conditions. Manufacturing facilities utilize tungsten carbide-based tools for precision machining operations, where the material's properties ensure extended tool life and superior surface finishes.

Technology Industry

The technology sector leverages tungsten carbide powder's unique properties in various applications. In the semiconductor industry, it creates high-precision tools for circuit board drilling and electronic component manufacturing. The material's electrical conductivity and wear performance make it valuable for producing specialized electrical contacts and switches. Advanced manufacturing processes in the technology sector rely on tungsten carbide tools for precise machining of complex electronic components and circuit elements.

Other Applications of Tungsten Carbide Powder

Beyond traditional industrial uses, tungsten carbide powder has applications in the aerospace, automotive, and energy sectors. The aerospace industry utilizes the powder in specialized coating applications for engine components and landing gear systems, where its resistance to deterioration helps protect parts exposed to extreme conditions during flight and landing operations. Automotive manufacturing applications include the production of abrasion-resistant components and high-performance engine parts, contributing to enhanced vehicle longevity and improved fuel efficiency through reduced friction and wear.

The energy sector uses tungsten carbide-based materials in components for power generation equipment and renewable energy systems, particularly in areas exposed to harsh environmental conditions or high mechanical stress. Mining operations benefit from tungsten carbide-coated drilling equipment and crushing components, significantly extending equipment life in these demanding environments. The material's unique properties are also valuable in emerging technologies such as fuel cell components and advanced energy storage systems, where its stability and durability provide crucial advantages. The medical industry has also begun exploring tungsten carbide powder applications in surgical instruments and specialized medical devices, taking advantage of its biocompatibility and durability.

Related: What is copper powder used for?

The Benefits and Limitations of Tungsten Carbide Powder

Advantages of Tungsten Carbide Powder

Tungsten carbide powder's properties deliver remarkable performance across diverse applications. Understanding these advantages is vital for engineers and technical professionals evaluating material solutions for demanding industrial environments:

- Exceptional wear performance leading to extended component life

- Superior hardness-to-toughness ratio for optimal cutting performance

- High thermal stability across varying temperature conditions

- Excellent chemical inertness and corrosion resistance

- Enhanced productivity through reduced maintenance requirements

- Cost-effective long-term performance in demanding applications

- Consistent mechanical properties at elevated temperatures

- Superior edge retention in cutting tool applications

- High compressive strength for structural integrity

- Excellent thermal conductivity for heat-intensive applications

Challenges of Tungsten Carbide Powder

While tungsten carbide powder offers numerous benefits, industrial professionals must consider its limitations and potential challenges when evaluating its use in specific applications. These considerations help ensure proper implementation and safe handling practices:

- High density that may impact weight-sensitive applications

- Complex processing requirements requiring precise parameter control

- Need for specialized handling and application equipment

- Potential risks from fine particle dust exposure

- Limited flexibility in post-processing modifications

- Higher initial investment compared to conventional materials

- Specific storage and handling requirements

- Training requirements for safe material handling

- Environmental considerations for disposal and recycling

Linde AMT's Tungsten Carbide Powder Solutions

Drawing on over five decades of materials expertise, Linde produces high-quality tungsten carbide cermet powders engineered for optimal performance in thermal spray and other industrial applications. Our manufacturing processes employ advanced technologies to ensure consistent particle size distribution, chemical composition, and morphology. We deliver tungsten carbide cermet powders that meet or exceed industry specifications for demanding applications through precise control of processing parameters and rigorous quality testing.

To address the complexities of tungsten carbide powder processing, our team provides comprehensive technical support and specialized equipment recommendations tailored to each customer's needs. We understand the challenges of parameter control and have developed standardized procedures that simplify implementation while maintaining product quality. Our solutions include detailed handling protocols and safety guidelines that minimize exposure risks and ensure worker safety.

We work closely with customers to optimize material usage and processing efficiency to help maximize return on investment. Our application engineers provide extensive training programs and ongoing support to ensure proper material handling and processing techniques. Additionally, we maintain strict environmental compliance standards and offer guidance on responsible disposal and recycling practices, helping customers meet their sustainability goals while maintaining operational excellence.

Through our global network of technical centers, we provide local support and rapid response to customer needs, ensuring consistent product quality and reliable supply chain management. This comprehensive approach helps customers overcome the traditional challenges of tungsten carbide-based powder implementation while achieving optimal application performance.

Why Choose Linde?

Linde provides comprehensive material solutions backed by extensive technical expertise and support. Our dedicated materials scientists and application engineers collaborate with customers to fine-tune powder properties such as particle size, distribution, and morphology to match exact application requirements. We maintain robust quality control systems and offer reliable global supply chain capabilities to ensure consistent product availability. For industrial professionals seeking high-performance tungsten carbide powder solutions, Linde delivers the expertise, quality, and support needed to achieve optimal results.

Contact our materials experts today to discuss how our tungsten carbide powder solutions can enhance your industrial applications.

FAQs

What is the typical particle size range for tungsten carbide powder?

Particle sizes typically range from 0.2 to 50 microns, depending on the specific application requirements.

How is tungsten carbide powder typically applied?

Common application methods include thermal spray processes, sintering, and powder metallurgy techniques.

What industries most commonly use tungsten carbide powder?

Primary users include manufacturing, mining, oil and gas, aerospace, and automotive industries.